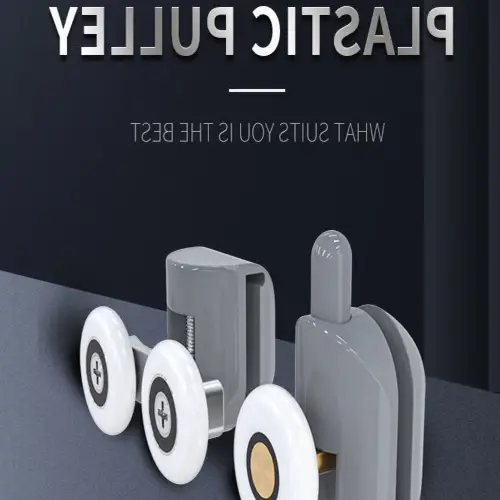

China Factory Fixed Plastic Bracket Pulley with Double Roller for Window and Door (ML-DD012) Small Air Compressor

Our Fixed Plastic Bracket Pulley with Double Roller for Window and Door (ML-DD012) is an essential component for sliding doors and windows, blinds, rolling shutters, furniture, and conveyor belts. Made with steel, zinc, aluminum, or plastic brackets and ball bearing or needle bearing wheels, this product ensures durability and smooth operation. The height of the roller is adjustable for some models, and the color of the wheel can be customized to red, green, white, orange, and more. The product comes with normal packing, which includes a poly bag and outer carton.

Why Choose Our Fixed Plastic Bracket Pulley with Double Roller?

With almost 20 years of experience in non-standard bearings, rollers, pulleys, and other plastic accessories for doors and windows, we have established a reputation as a reliable and professional manufacturer. Our products are popular all over the world, with over 20 market countries. We take pride in offering good quality products at competitive prices, and we are happy to offer OEM services for technical drawings, samples, or photos. Our company is committed to providing considerate services to our customers, and we welcome customization requests.

Our Other Products for Industrial Use

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are dedicated to providing high-quality products, preferential prices, and considerate services to our customers. Please feel free to contact us for any inquiries or customization requests.

Frequently Asked Questions

1. What is the material used for the Fixed Plastic Bracket Pulley with Double Roller?

Our Fixed Plastic Bracket Pulley with Double Roller is made with steel, zinc, aluminum, or plastic brackets and ball bearing or needle bearing wheels, ensuring durability and smooth operation.

2. Can the height of the roller be adjusted?

Yes, for some models, the height of the roller is adjustable.

3. What is the normal packing for the product?

The product comes with normal packing, which includes a poly bag and outer carton.

4. Can the color of the wheel be customized?

Yes, the color of the wheel can be customized to red, green, white, orange, and more.

5. Does your company offer OEM services?

Yes, we offer OEM services for technical drawings, samples, or photos.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Plastic Pulley

Plastic pulleys offer several performance characteristics that make them suitable for various applications. Firstly, they are lightweight, which allows for easy installation and reduces overall system weight. Secondly, plastic pulleys are corrosion-resistant, making them ideal for applications in humid or corrosive environments. Additionally, they have low friction coefficients, resulting in smooth and efficient operation. Furthermore, plastic pulleys are known for their excellent wear resistance and durability, ensuring a long service life. Lastly, they can provide noise reduction and vibration damping, contributing to a quieter and more stable system.

Types and Characteristics of Plastic Pulley

There are different types of plastic pulleys available, each with its own unique characteristics. One common type is the solid plastic pulley, which offers high strength and rigidity. Another type is the nylon pulley, known for its excellent heat resistance and impact strength. Additionally, there are plastic pulleys with ball bearings, which provide smoother rotation and improved efficiency. Furthermore, some plastic pulleys are designed with grooves or teeth to enhance traction and prevent slippage.

Advantages of Plastic Pulley Made of Different Materials

Plastic pulleys can be made of various materials, each offering distinct advantages. For instance, polyethylene (PE) pulleys are known for their high chemical resistance, making them suitable for applications involving exposure to chemicals. On the other hand, polypropylene (PP) pulleys are valued for their excellent thermal stability and resistance to fatigue. Additionally, polycarbonate (PC) pulleys exhibit high impact strength and transparency, making them suitable for applications that require visibility. Each material has its own unique properties that can be tailored to specific application requirements.

Application of Plastic Pulley in Various Fields

Plastic pulleys find extensive use in diverse industries, showcasing their value and importance. In the Automotive Industry, plastic pulleys are commonly used in engine systems, steering systems, and timing belt systems. In Consumer Electronics, they are utilized in printers, copiers, and other electronic devices. Industrial Machinery often incorporates plastic pulleys in conveyor systems and power transmission systems. Medical Equipment relies on plastic pulleys for applications such as hospital beds and medical devices. Moreover, Appliances such as washing machines and refrigerators utilize plastic pulleys for various mechanical functions. The versatility of plastic pulleys makes them indispensable in numerous fields.

Future Development Trends and Opportunities of Plastic Pulley Products

The plastic pulley industry is expected to witness significant growth in the coming years. One notable trend is the increasing demand for environmentally friendly materials, prompting the development of eco-friendly plastic pulleys. Additionally, advancements in manufacturing technologies, such as injection molding, are enabling the production of complex and custom-designed plastic pulleys. Furthermore, the expansion of industries such as renewable energy and electric vehicles presents new opportunities for the application of plastic pulleys. With continuous innovation and adaptation to market demands, the future of plastic pulley products looks promising.

Choosing a Suitable Plastic Pulley

When selecting a plastic pulley, several factors should be considered. Firstly, the load capacity is crucial to ensure that the pulley can withstand the anticipated forces. Secondly, the material of the pulley should be chosen based on the specific requirements of the application. Different materials offer varying levels of strength, heat resistance, and chemical resistance. Additionally, the diameter and size of the pulley should be compatible with the system’s requirements. The type of pulley, such as solid or with ball bearings, should be selected based on the desired functionality. Lastly, the bore size should match the shaft diameter for proper installation and operation.

In conclusion, plastic pulleys possess a range of performance characteristics that make them suitable for various applications. Their versatility, combined with different types and materials, allows for customized solutions. Plastic pulleys find widespread use in different industries, reflecting their value and importance. As the industry continues to evolve, new trends and opportunities present themselves, ensuring a bright future for plastic pulley products. By considering factors like load capacity, material, diameter, type, and bore size, one can choose a suitable plastic pulley for their specific needs.